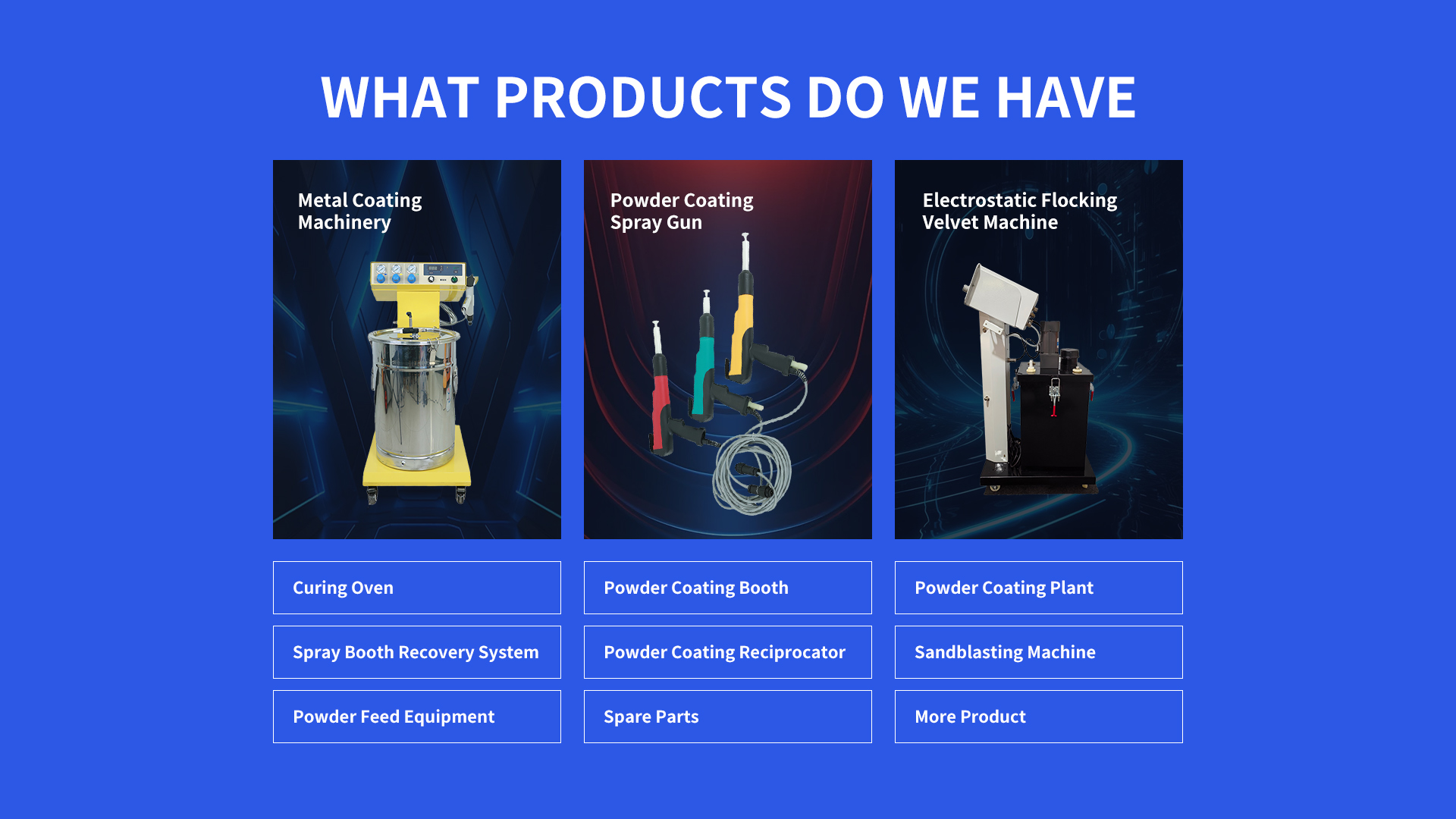

1. Industrial Powder Coating Line Equipment Overview and Components

An Industrial Powder Coating Line integrates pretreatment stations, electrostatic spray booths, curing ovens, and conveyor systems. Pretreatment removes contaminants via chemical cleaning or abrasive blasting. Electrostatic spray guns apply charged powder particles to metal surfaces, ensuring uniform adhesion. Curing ovens thermally fuse the powder into a durable finish. Automated conveyors streamline production, making these systems ideal for high-volume manufacturing.

2. Industrial Powder Coating Line Applications Across Industries

Automotive, construction, and electronics industries rely on powder coating lines for corrosion-resistant finishes on car parts, structural steel, and electrical enclosures. Home appliances like refrigerators and washing machines also use these lines for scratch-resistant surfaces. The process supports sustainability goals by eliminating volatile organic compounds (VOCs).

3. Industrial Powder Coating Line Equipment Cost Factors

Prices range from 15,000formanualsystemsto600,000+ for fully automated setups. Key cost drivers include oven size, conveyor speed, and energy efficiency. Modular designs reduce initial investments, while advanced powder recovery systems lower long-term material waste by 25–40%.

4. Best Practices for Operating Industrial Powder Coating Lines

Calibrate spray guns to maintain consistent powder flow and voltage. Preheat ovens to 160–210°C for optimal curing. Ground all equipment to prevent electrostatic discharge. Clean spray booths daily to avoid cross-contamination and ensure adherence to OSHA safety standards.

5. How to Select Industrial Powder Coating Line Equipment

Assess production needs: batch size, substrate materials, and facility space. For small workshops, benchtop systems offer affordability. Large factories require automated lines with high-speed conveyors. Prioritize vendors providing ISO-certified equipment and on-site training.

6. Industrial Powder Coating Line Safety Guidelines

Install explosion-proof lighting in spray booths to mitigate fire risks. Use NIOSH-approved respirators to protect against airborne particles. Regularly inspect electrical systems and grounding mechanisms. Train staff on emergency protocols for oven malfunctions or powder spills.

7. Design Efficiency in Industrial Powder Coating Lines

Modern lines emphasize energy recovery and waste reduction. Infrared curing ovens cut energy use by 30%, while closed-loop powder reclaim systems recycle unused material. Modular layouts allow easy upgrades, adapting to evolving production demands.

8. Industrial Powder Coating Line Equipment FAQs

Q: Which industries benefit most from powder coating equipment?

A: Automotive and construction sectors prioritize powder coating for rust-proof metal components.

Q: How to reduce Industrial Powder Coating Line maintenance costs?

A: Schedule monthly inspections and use high-quality filters to extend equipment lifespan.

Q: Are powder coatings suitable for outdoor applications?

A: Yes, UV-resistant powders protect outdoor machinery from weathering.

Q: What impacts Industrial Powder Coating Line efficiency?

A: Conveyor speed, oven temperature consistency, and powder application accuracy.

Q: Can powder coating lines handle mixed-material products?

A: Yes, adjustable settings accommodate metals like aluminum, steel, and alloys

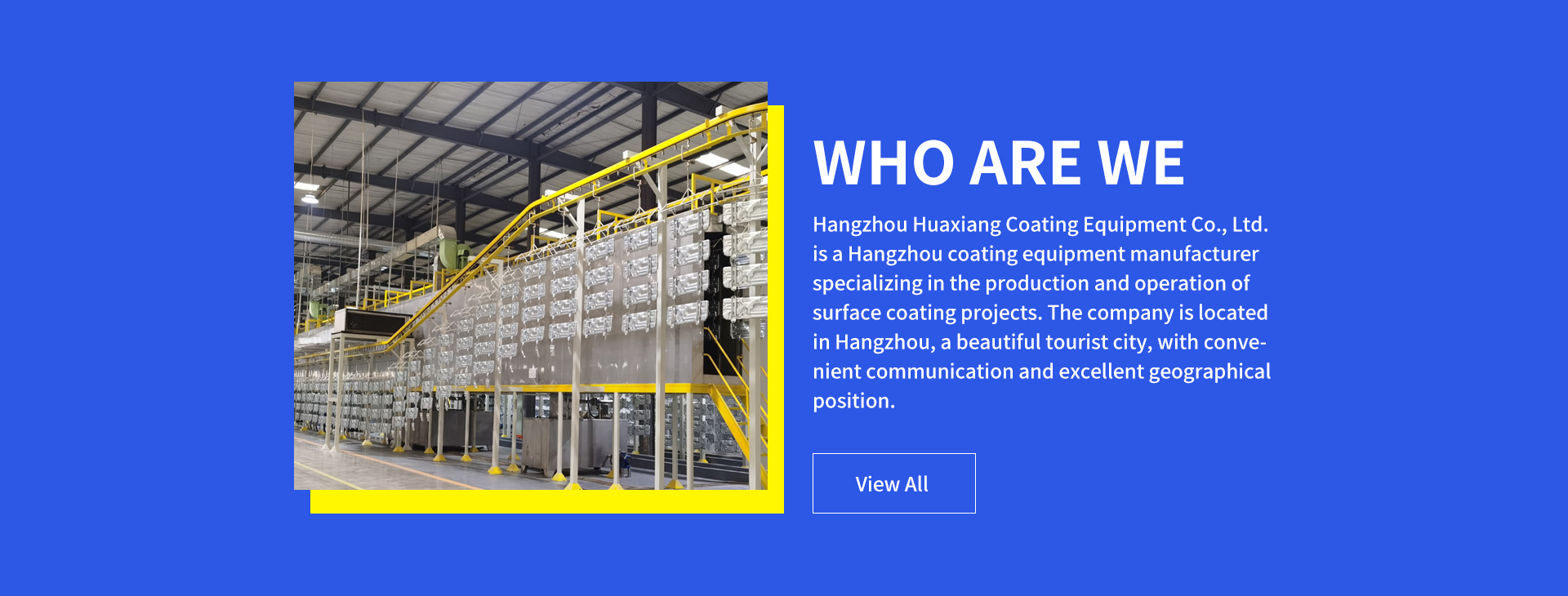

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com